Top Six Food Safety Mistakes made by food businesses

Table of Contents

Schools and academies that provide catering to staff and pupils are in effect food businesses and fall under the same inspection standards that applies to any other food business. When inspecting food businesses, Environmental Health Officers very often find mistakes that generally result in a poor Food Hygiene Rating for the business and leave the business facing a rapidly diminishing customer base as word gets around that they have a poor hygiene score. The business then have to consider paying for a re-rating inspection or trying to wait for the next routine inspection 6, 12 or even 18 months later in order to try to improve.

However, it doesn't have to be like this. There are several mistakes that Environmental Health Officers (EHOs) see time and time again, particularly with new food businesses. These are generally easy to rectify and will often significantly improve the Food Hygiene Rating received by the business.

1. Inadequate separation of raw and ready to eat foods

The prevention of contamination and the removal of contamination in food that will be eaten without any further processing (such as cooking) is fundamental to making sure that it is safe to eat. This may sound obvious, but it is surprising how often this basic principle is ignored. The main areas where this can occur is in delivery, storage and preparation.

If you collect food from a cash & carry or supermarket, make sure that raw meat and dirty soil covered vegetables are not packed with ready to eat food such as salads, fruit or cooked food or dairy items. Keep foods that are likely to be contaminated in separate bags to other foods. When you get food delivered, reputable companies should have procedures in place to make sure that contaminated food is kept separated, however some delivery drivers cut corners or ignore procedure, so be vigilant.

When food is put into storage in a fridge or freezer, remember that the separation of raw and ready to eat food must continue. Always put raw meat and dirty vegetables on the bottom shelves of the fridge and the ready to eat foods at the top. This prevents drips of blood, meat juices or soil from falling onto ready to eat food. Even better is to have separate fridges for raw meat and dirty vegetables away from the ready to eat foods fridge. Remember that food can still get contaminated in a freezer. Use the same storage plan in upright freezers. If you have a chest freezer, use a vertical separator to keep ready to eat foods separate from raw meat. Also, remember to defrost your freezer regularly, you don't want blood-soaked ice crystals sprinkling over the ice cream container!

When preparing food, it is always important to again have adequate separation between raw and ready to eat foods. Ideally, raw meat and dirty vegetables should be prepared in a separate room with separate washing facilities and staff. In many food businesses, this isn't always possible due to lack of resources or space. If this is the case, there will hopefully be space within the same room to have a separate preparation table to use only for raw meat and/or dirty vegetables. If your business does not have the space to separate food preparation areas, the same surface can be used for both raw and ready to eat foods, but never at the same time. You will need to plan your preparation carefully and ensure that the whole area has been thoroughly cleaned and disinfected after use.

Pay attention to what is stored below food preparation surfaces, EHOs often find containers used for ready to eat foods stored on shelves below the raw meat prep surface. This means that dirt and meat juices can fall into these containers which are then used for ready to eat foods such as salad, cooked meats or cheese.

2. Inadequate personal hygiene

It is easy to forget the people handling food are a contamination risk. EHOs often find small businesses where staff wear their own outdoor clothes throughout the working day. Take a minute to think about what that staff member might have been doing before work.

- They may have had a pet sitting on their lap before work.

- They may have put out their bins or leaned against a tree.

- They may have picked up a heavy box that was sitting on a filthy pavement.

Do you really want that person wearing the same clothes making sandwiches? Make sure that food handlers always wear clean clothing that they only wear at work for handling food. They must not wear the same clothing when handling raw meat and dirty vegetables as ready to eat foods. Provide separate, preferably disposable aprons to protect their clothes when handling raw meat and dirty vegetables or doing dirty jobs in the kitchen such as emptying bins or deep cleaning. They can then remove the apron and wash their hands before going on to other activities.

Hand washing is also an important control in the prevention of contamination. It is important for food handlers to wash hands regularly and after touching things that might contaminate them such as raw meat, the waste bin or after going to the toilet. It is often easy for EHOs to spot food premises where hand washing is not done regularly, the hand contact surfaces tend to be dirty or sticky after being touched by dirty hands. Hand washing, if done incorrectly, can make the contamination worse. Always have enough liquid hand soap and a means of drying hands hygienically. Disposable paper towels are the best option, particularly if the wash hand basin has hand operable taps. In these circumstances the EHO will expect to see the person washing their hands and then using the paper towel they have used to dry their hands, to turn off the taps. This avoids touching the same taps touched a few seconds ago when hands were dirty.

3. Inadequate disinfection

Food preparation surfaces and equipment must be protected from contamination and disinfected properly. For equipment, this is best done in a mechanical dishwasher. This is because the heat in a dishwasher is sufficient to kill any bacteria remaining on equipment.

If you wash equipment by hand, the water used cannot be hot enough to thermally disinfect equipment without seriously scalding the person carrying out the task. It is for this reason that if the business does not have a dishwasher, any equipment that has previously been in contact with raw meat or dirty vegetables should never come in to contact with ready to eat foods or other equipment used for ready to eat foods. Make sure that you can easily identify which equipment is which by using different coloured or shaped equipment for raw meat and ready to eat foods. They must not be stored together. A typical failing that lets food businesses down is the storage of chopping boards. They are often stored on rack and so food handlers stack the yellow board next to the red. You need to keep them apart in different areas of the room at the very least.

Food and hand contact surfaces must be kept clean and disinfected. EHOs will:

- expect you to use a sanitiser or disinfectant that complies with BS EN 1276 or BS EN 13697.

- want to be sure that you know how the disinfectant is prepared. Does it need to be diluted and if so, do you and all staff know how to do this properly?

- want to know that you know how to use the product including how long the contact time is.

- want to know that everyone in the business knows how to two-stage clean and disinfect a surface, so that the disinfection is effective.

4. Inadequate temperature control

If food is kept in the temperature danger zone bacteria can grow quickly. It is important that you check your refrigeration regularly to make sure that food is kept at the right temperature. Very often fridges have a temperature display on the front. However, don't be fooled by this! Some fridge manufacturers locate the temperature sensor for this display near or even inside the chilled air outlet in the fridge. This is the coldest part of the fridge and is not an accurate measure of the temperature of the food in the fridge. Ultimately, the EHO will do their own checks on the food and often this is far above what is on the digital display. Purchase your own Infrared Thermometer, they are less than £20 and can be used to check the surface temperatures of a number of food items in each fridge within a few seconds.

If you are hot-holding food make sure that you do it correctly. Never add cold food to a Bain Marie or hot cabinet, they are not designed to reheat food and so the food stays in the temperature danger zone (8°C to 63°C) far too long. Always cook food thoroughly or reheat food to at least 75°C first (83°C in Scotland) before moving it to hot hold. Make sure that the food remains above 63°C while held hot. Use a thermometer to check this regularly.

5. Poor pest control

No matter how well your food is prepared, if you have a pest problem, you will have a significant problem at a food inspection. You will be lucky if you are not closed on the spot. It is surprising how often pests are found and there are always two common issues: inadequate cleaning and poor pest proofing.

Pests usually need three factors present to thrive:

- a quiet place to hide

- a water source, and

- a food source

The quiet place to hide is often easy to find in a commercial kitchen, this could be under equipment such as in the compressor compartment of fridges, under a deep fat fryer, or in a hole in a wall. Water is easy for pests to find in drains or in the condensation tray in the back of a fridge. Food is the key factor that you need to control. Make sure that cleaning, especially low-level cleaning is thorough. Never allow food, oil or fat in a place accessible to pests. High calorie food is a favourite so be particularly careful with oil and grease spills from ovens and fryers or fallen chips in dark corners. Make sure open foods are stored in pest proof containers.

The best way to prevent pest problems is to stop pests getting into your premises. Pest proofing is usually a very good investment and is generally cheap. Pest proofing advice is often overlooked and is the single most effective way of preventing a pest problem. Carry out regular checks of your premises looking for possible entry holes. You will need:

- A pencil, which has a diameter of about 5 mm to stick in holes and under doors to see if you can find a way in.

- A torch to look in all the darkest corners.

- Wire wool to stuff into the bigger holes before covering it over with filler. You could also use mastic sealant or expanding foam. Any such work should be regularly checked to ensure it is still in place.

A mouse can squeeze through a hole as small as 5mm in diameter so use the pencil to search out these holes. Look around pipes as they enter walls, in electricity and gas meter boxes and under doors. Look at internal and external walls to prevent mice finding their way into wall cavities and ceiling spaces. Be as thorough as you can, it only needs you to miss one entry point for there to be a problem.

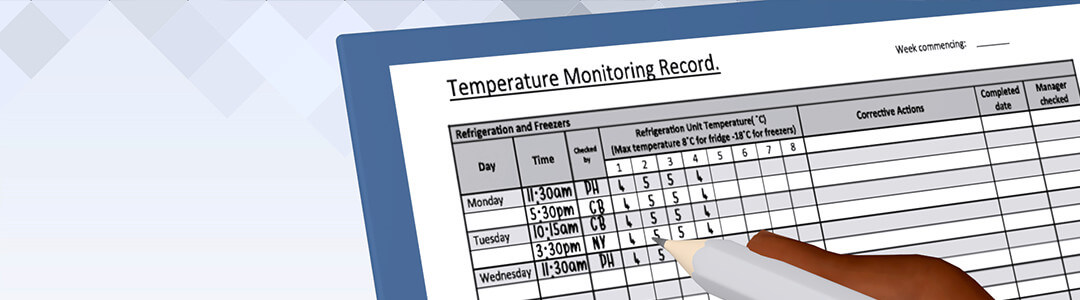

6. Inadequate Food Safety Management System and Monitoring

A major mistake that some food businesses make is not having or valuing a Food Safety Management System. There is a strong temptation for food businesses to consider that this is just something to keep the council off their backs and to think that they have more important things to do with their time. EHOs see this time and time again and these businesses almost always score badly. It is not because they haven't had the chance to fill in their temperature records for the last week or so before the EHO asks to see them. The reason is that the checks are not being done. If monitoring records are falsified, then problems go unnoticed. These problems can put your customers at risk and will be quickly picked up by an EHO. For example,

- If your records say that the fridge temperature is always 5°C but when measured is found to be 12°C, then why weren't you aware of this?

- If your records say that you cleaned the hand contact surfaces every day and the fridge door is covered in old sticky and greasy marks, then why wasn't this cleaned?

- If you say that you check every morning that there is enough hand soap and paper towels at each wash hand basin, why is there no hand soap available at 11am and all the paper towel dispensers are empty?

All these failures indicate that checks are not being done. Not doing checks puts your customers at risk and so a poor rating score is entirely justified. Likewise, if your food safety management system such as Safer Food, Better Business, Cook Safe or a HACCP document does not detail how you ensure that the food that you produce is safe, then that indicates that you have not properly considered the risks and problems that you could encounter, and what to do if something doesn't work out as planned.

The Food Safety Management System is that cornerstone of consistently producing safe food. However, it is of no use if food handlers don't know where to find the document or what it says. Every food handler needs to know what to do to produce safe food at your food premises. You need to ensure that every food handler has read these documents and understands their role in keeping food safe. In order to do this food handlers need to have a general understanding of food safety by being trained in food hygiene. This can be done quickly and cost effectively by enrolling on our Level 2 Food Safety and Hygiene course.

If a food business is well run, new staff will be trained and all other staff will receive routine refresher training every 3 years, so that managers can be confident staff know how to keep your customers safe.

By having a well-considered and effective Food Safety Management System, including detailed and effective monitoring and management systems, a food business will be on top of problems as and when they occur and more often than not prevent them from happening in the first place. All of the issues discussed in this article should be covered in a good Food Safety Management System. If you get this right, the rest will follow. Ignore it and don't be surprised if your next food hygiene inspection doesn't go as well as you hoped.

Jonathan Case BSc (Hons) Env Health

SSS Learning Limited

1 February 2022